I often say “A defect is a jewel to be treasured” to coworkers. The idea being rather than ignoring or hiding a defect we should try to understand how this defect arose and what it can teach us about improving.

Yet too often I see almost the opposite approach in the solar industry. Last year I wrote about how how municipal governments were ignoring the problems with systems they had installed. I showed examples in the Region of Waterloo and then Metrolinx and was met with a giant yawn and indifference.

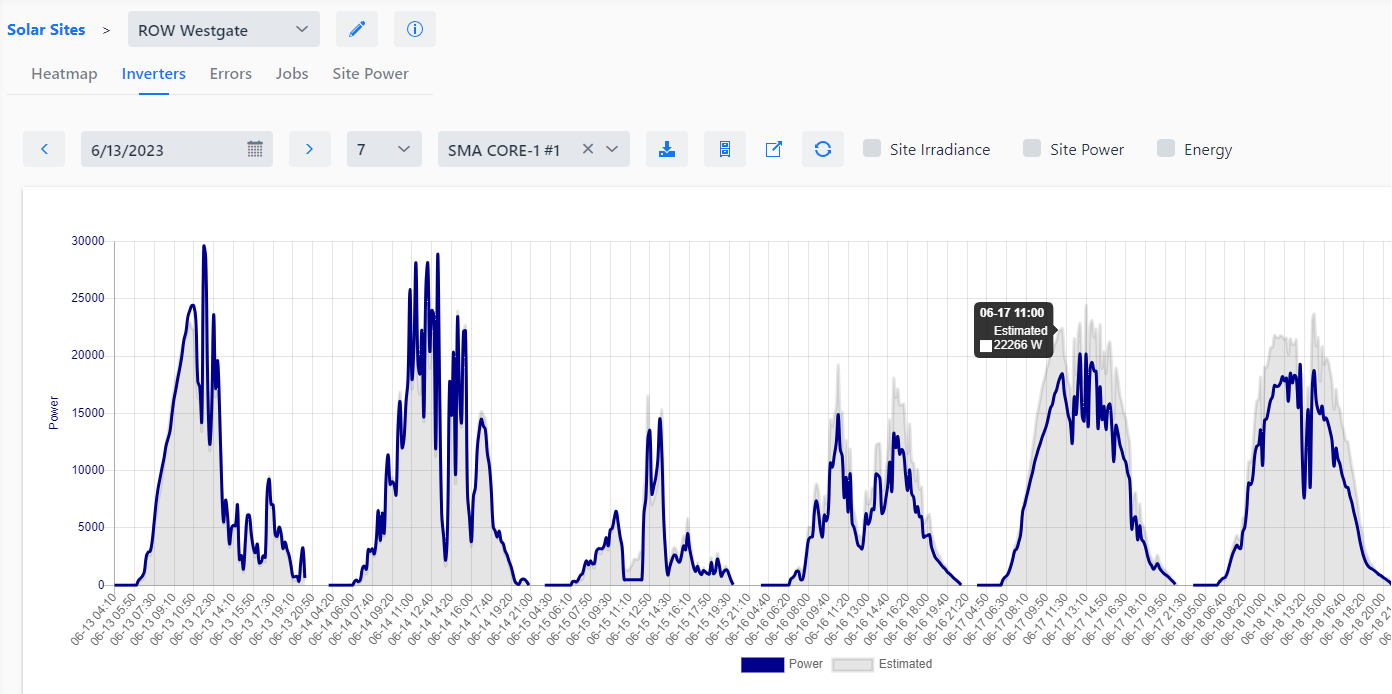

At least with the Region of Waterloo, I got a response and apparently parts were ordered to replace an inverter at their Westgate location which had lost over $200,000 after going unrepaired for two years. Unfortunately one of the replacements had a string go down in June 2023 as you can see in a graph from our platform below.

You can’t see this as easily in the public portal they use for monitoring except for the drop in production in June. What has the Region’s response been to these problems? Well the solution is apparently to throw away their working inverters and replace them as you can see in this RFP which has now been awarded.

How much money prior to this RFP was spent on staff time and consulting contracts to come up with this solution to a defect? If this was your money would you take this approach? I don’t think so and let me share a story that involves a defect I failed to detect and learn from soon enough.

Over four years ago, I was introduced to what is now a Boxbrite customer whose 320kW system was underperforming. We started looking at the data on the 29 inverters down to the MPPT level. There were multiple issues, including shading, soiling, north facing panels, etc. However, one thing in particular that puzzled us was their best south facing inverters seemed to underperform but we didn’t know why.

They didn’t become a customer at that point but almost two years ago we started looking at their system again. They were having inverter failures and struggling to get replacements and so we did a full assessment based on everything we had learned. Again I took a look at the underperformance and came up with a hypothesis. Those inverters had two MPPTs each which could be configured to operate independently or in parallel. On this site most were supposed to be configured for parallel but the current and power curves on those four inverters appeared abnormal.

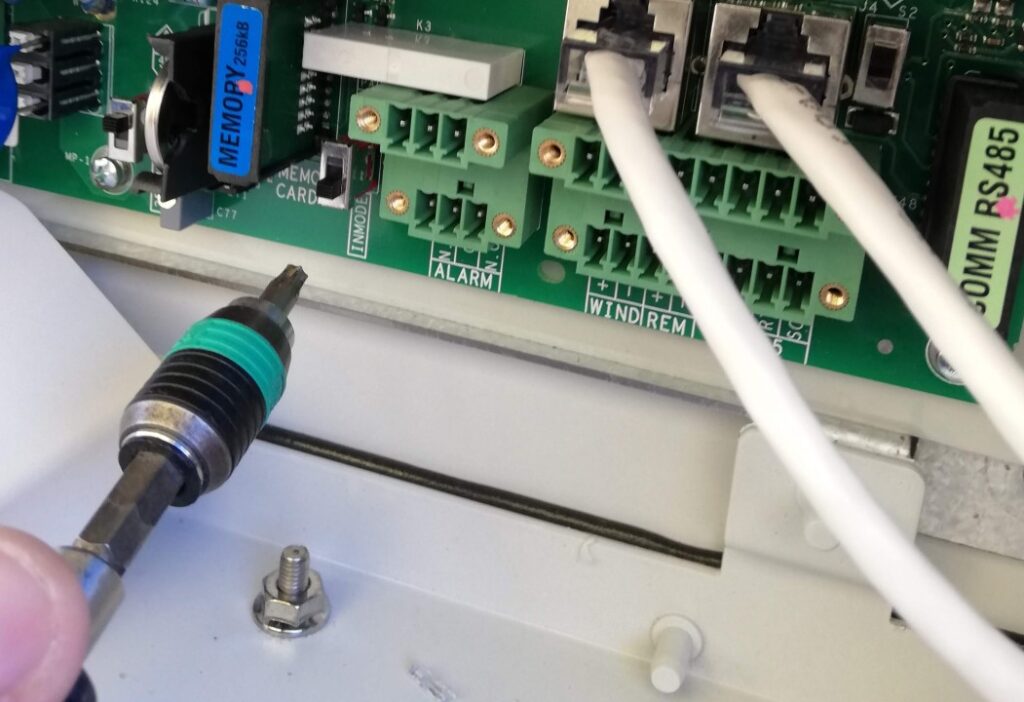

The above photo was taken when we opened up one of the inverters and found that yes the small switch hadn’t been configured correctly when the system went live in 2015. I didn’t make that original mistake but we failed to catch it in 2019 and my calculations showed the system owner was losing about $5,700 per year because we didn’t treasure that defect enough. However, I now have been able to apply that knowledge on new systems we are examining because it turns out that this problem is a lot more common than you might expect.

The bitter irony for me was that because so many inverters had failed and replacements weren’t available the customer ended up needing to repower 50% of the system including those inverters. This freed up enough hot spares to hopefully carry them through the rest of their 20 year contract. My solution came too late to be of any real value. The owner never said why don’t I just throw all my inverters away and buy new ones because I’m having some problems but considered the most cost effective approach.

My question is why isn’t the Region taking a similar approach to their defects? What is their business case for replacing all of these inverters with less than 8 years left in their 20 year FIT contract? How are they going to prevent the same problems from emerging as the Westgate replacements? What options have they considered?

Often we hear that the definition of insanity is doing the same thing and expecting different results. How can we solve climate change if we don’t learn from our mistakes?